量子效率测试仪

PL/EL一体机

Sinton硅片少子寿命测试仪

Sinton硅块少子寿命测试仪

绒面反射率测试仪

3D共聚焦显微镜

清洗制绒工作站

在线四探针方阻测试仪

全自动扫描四探针方阻测试仪

在线薄膜厚度测试仪

晶化率测试仪

Horiba高速高分辨显微共焦拉曼光谱仪

傅里叶红外光谱仪

霍尔效应测试仪

分光光度计

全光谱椭偏仪

Horiba椭圆偏振光谱仪

TLM接触电阻率测试仪

超景深显微镜

网版智能影像测量仪

全自动影像测量仪

卧式拉力机

电池片稳态光衰老化试验箱

电池片紫外老化试验箱

电池片拉脱力综合测试仪

外观检验台

湿漏电测试系统

组件实验室EL测试仪

紫外老化试验箱

稳态光衰老化试验箱

电流连续性监测系统

PID测试系统

旁路二极管测试系统

LeTID测试系统

反向电流过载系统

脉冲电压测试系统

绝缘耐压测试仪

接地连续性测试仪

绝缘耐压接地测试仪

湿热环境试验箱

湿冻环境试验箱

热循环试验箱

动态机械载荷测试机

静态机械载荷测试机

冰雹冲击试验机

引出端强度试验机

霰弹冲击试验机

抗划伤(切割)测试机

剥离试验机

万能材料试验机(单臂)

万能材料试验机(双臂)

光伏玻璃透过率测试仪

醋酸测试试验箱

交联度测试系统

二极管接线盒综合测试仪

落球冲击试验机

半自动四探针

全自动探针式台阶仪

复合式LED模拟器

多通道太阳能MPPT系统

LED模拟器光浴

Horiba高灵敏一体式稳瞬态荧光光谱仪

钙钛矿P1激光划线测试仪

钙钛矿在线膜厚测试仪

钙钛矿工艺检测工作站

手持式IV测试仪

便携式EL测试仪

手持热成像测试仪

户外组件IV测试仪

户外组件多通道测试系统

光伏逆变器电能质量测试仪

无人机EL检测仪

Poly层厚度对N型TOPCon太阳能电池电学性能的影响

日期:2024-08-09

具有超薄氧化硅SiOx薄膜和掺磷多晶硅Poly层的TOPCon太阳能电池具有高达28.7%的理论效率极限,成为目前行业的研究热点技术。TOPCon电池在金属与硅接触界面表现出优越的钝化质量,具有更高的载流子选择性和更低的复合率。但不同厚度的n+Poly层会对金属化接触形成的微观结构、钝化效果和电池的电学性能产生影响。美能在线Poly膜厚测试仪专为光伏工艺监控设计,帮助客户准确获得样品不同位置的膜厚分布信息,实时监控工艺的稳定性,从而优化薄膜厚度。

掺杂的多晶硅通常是经过高温热处理后从非晶硅层a-Si结晶而成。通常,制备的方法包括PECVD、LPCVD、常压CVD、高压CVD、溅射和电子束蒸发。通过对钝化接触的参数,比如对SiOx薄膜和Poly层的结构性质和厚度以及钝化触点的金属化进行研究,可以为沉积制备工艺参数对Poly层和电池性能的影响提供有价值的见解。

TOPCon太阳能电池结构示意图

通过控制SiOx薄膜的界面缺陷和Poly层的掺杂浓度,掺杂后的Poly层可以获得良好的钝化性能和较低的接触电阻率。通过控制沉积工艺方法可以改变Poly层的厚度,不同厚度会对发射极的饱和电流密度、金属化复合和接触电阻率ρc产生影响。

以下我们通过对厚度为30nm、50nm、70nm、100nm的多晶硅Poly层进行测量与分析。

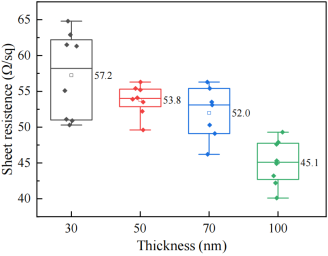

薄层电阻R□

当n+Poly层厚度从100nm减小到30nm时,电池片的薄层电阻(R□)从45.1增加到57.2Ω/sq。这是因为Poly层的厚度决定了总掺杂量。虽然表面掺杂浓度相同,随着厚度的不断增加,总掺杂量也在增加,导致电池片的薄层电阻降低。

不同n+Poly层厚度TOPCon太阳能电池薄层电阻图

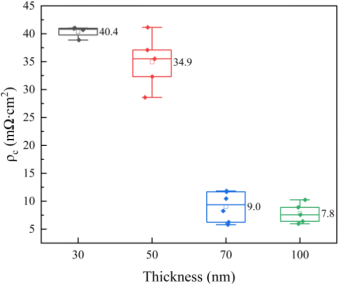

接触电阻率ρc

当n+Poly层的厚度从30nm增加到100nm时,接触电阻率显著降低。随着厚度增加,总掺杂浓度也随之增加,从而使硅片内部的耗尽区宽度变窄,促进了载流子通过肖特基势垒的量子隧穿效应。较厚的Poly层能够提供更多的掺杂原子,减少接触电阻率。

不同n+Poly层厚度TOPCon太阳能电池接触电阻率ρc图

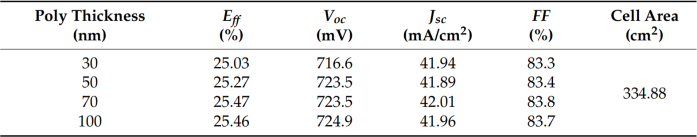

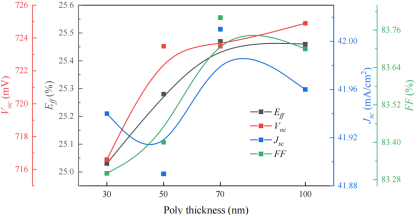

I-V参数

较薄的n+Poly层(30 nm)由于无法提供足够的掺杂浓度和钝化效果,导致效率Eff和开路电压Voc较低。在n+Poly层厚度为70 nm和100 nm时,太阳能电池的效率Eff、开路电压Voc和填充因子FF均达到最佳状态。这表明,这两个厚度能够提供良好的电性能和平衡的掺杂浓度与电阻特性。

表.不同n+Poly层厚度TOPCon太阳能电池的I-V参数

不同n+Poly层厚度TOPCon太阳能电池的I-V参数

从上述中可以得出结论,Poly层的厚度对TOPCon太阳能电池的电学性能有显著影响。较厚的Poly层具有较低的薄膜电阻,能够提供更高的导电性。这也表明在设计和制造太阳能电池时,需要优化Poly层的厚度,这对于实现高效TOPCon太阳能电池至关重要。

美能在线Poly膜厚测试仪

联系电话:400 008 6690

美能在线Poly膜厚测试仪,可完成薄膜厚度精确检测的同时衔接于产业化检测工序中,使电池厂商在沉积工艺产线中,运用该设备进行大规模的系统化检测,从而帮助电池厂商大大节约检测时间、提高生产效率与质量保证!

■ Poly膜厚测试范围20nm-2000nm

■ 快速、自动的5点同步扫描

■ 非接触、无损测量,零碎片率

■ 24小时自动且不停线校准,保证生产效率

在实际应用中,优化Poly层的厚度能够在性能和成本之间取得更好的平衡,实现n-TOPCon太阳能电池的整体效率和经济性。美能在线Poly膜厚测试仪专为光伏工艺监控设计,帮助客户准确获得样品不同位置的膜厚分布信息,实时监控工艺的稳定性,从而优化薄膜厚度。